I am getting there!

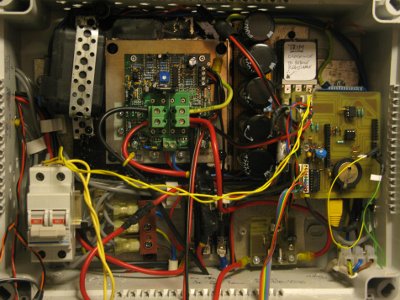

With a new LDR Controller in place (see photo on left), a proper Shield I have built for the Arduino Monitor, and wiring re-routed all I was waiting for was a new Immersion Heater.

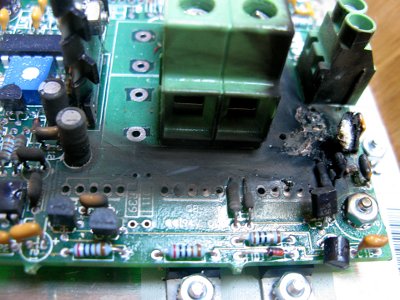

The new one arrived and the old one taken out. Nothing to see on inspection, but you can see the considerable difference in quality between these two items. The new one is the bigger heater fitting flush inside the tank, unlike the other one which is smaller, has very tight bends, and is not flush with tank, so I think would risk overheating. A possible cause for it's failure.

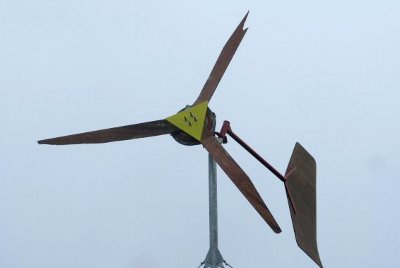

29th April 2012 The turbine has been running all day in winds from 5 - 35 knots. It is producing about 1kW when wind is above 20knts, so doing really well...... Watch this space!